A centre drill is a form drill that drills a locating hole in the centre of a workpiece for turning or grinding. It is widely used in machining, machinery, shipbuilding and other industries. Centre drills are usually made of high speed steel (HSS). The geometry of these drills is characterised by the short length of the front end and the stepped shape of the tool. The diameter of the front part is the nominal diameter of the tool, ensuring high centring accuracy in the hole.

Solid carbide center drill, part of a versatile carbide drill bit set, designed for precise centering and enhanced durability in deep hole machining.

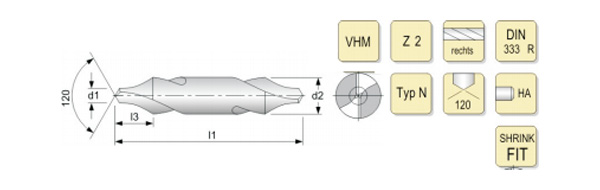

Engineering Data

four-sided grinding

spiral fluted

| d1 | d2 | dl | d2 | |||||

| DIN | L3 | L1 | (h6) | DIN | L3 | L1 | (h6) | |

| mm | mm | mm | mm | mm | mm | mm | mm | |

| 0.5 | 2.12 | 25 | 3.15 | 2.5 | 6.7 | 45 | 6.3 | |

| 0.8 | 2.65 | 25 | 3.15 | 3.15 | 8.5 | 50 | 8 | |

| 1 | 3 | 31.5 | 3.15 | 4 | 10.6 | 56 | 10 | |

| 1.25 | 3.35 | 31.5 | 3.15 | 5 | 13.2 | 63 | 12.5 | |

| 1.6 | 4.25 | 31.5 | 4 | 6.3 | 17 | 71 | 16 | |

| 2 | 5.3 | 40 | 5 |

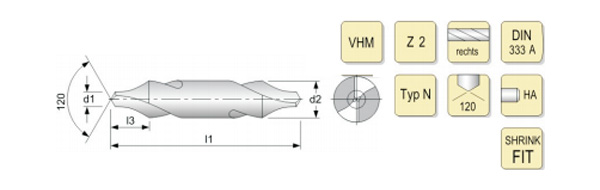

Engineering Data

four-sided grinding

spiral fluted

| dl | d2 | dl | d2 | |||||

| DIN | L2 | Ll | (h6) | DIN | L3 | L1 | (h6) | |

| mm | mm | mm | mm | mm | mm | mm | mm | |

| 0.5 | 3 | 25 | 3,15 | 2.5 | 3 | 45 | 6.3 | |

| 0.8 | 1.1 | 25 | 3.15 | 3.15 | 3.9 | 50 | 8 | |

| 1 | 13 | 31.3 | 3.15 | 4 | 5 | 56 | 10 | |

| 1.25 | 1.6 | 31.3 | 3.15 | |||||

| 1.6 | 2 | 35.3 | 4 | 5 | 6.3 | 63 | 12.5 | |

| 2 | 2.5 | 40 | 5 | 6.3 | 8 | 71 | 16 |

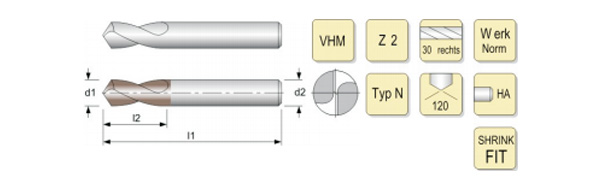

Engineering Data

pilot drill

short flute length

point ground:relieved cone

| dl | d2 | dl | d2 | |||||

| (h6) | L2 | L1 | (h6) | (h6) | L2 | L1 | (h6) | |

| mm | mm | mm | mm | mm | mm | mm | mm | |

| 5 | 10 | 62 | 5 | 12 | 25 | 102 | 12 | |

| 6 | 15 | 66 | 6 | 16 | 35 | 115 | 16 | |

| 8 | 20 | 79 | 8 | 20 | 40 | 131 | 20 | |

| 10 | 22 | 89 | 10 |

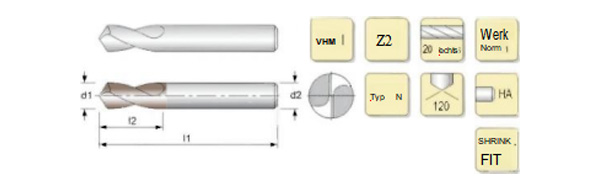

Engineering Data

pilot drill

short flute length

point ground: relieved cone

| d1 | d2 | d1 | d2 | |||||

| (h6) | L2 | L1 | (h6) | (h6) | L2 | L1 | (h6) | |

| mm | mm | mm | mm | mm | mm | mm | mm | |

| 5 | 10 | 62 | 5 | 12 | 25 | 102 | 12 | |

| 6 | 15 | 66 | 6 | 16 | 35 | 115 | 16 | |

| 8 | 20 | 79 | 8 | 20 | 40 | 131 | 20 | |

| 10 | 22 | 89 | 10 |

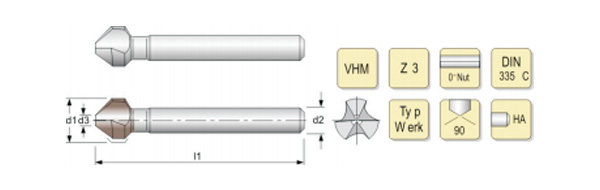

Engineering Data

three cutting edges

for counterbores acc

DIN 74

| d1 | d2 | d1 | d2 | |||||

| (z9) | d3 | L1 | (h7) | (z9) | d3 | L1 | (h7) | |

| mm | mm | mm | mm | mm | mm | mm | mm | |

| 6.3 | 1.5 | 45 | 5 | 15 | 3.2 | 60 | 10 | |

| 8.3 | 2 | 50 | 6 | 16.5 | 3.2 | 60 | 10 | |

| 10.4 | 2.5 | 50 | 6 | 20.5 | 3.5 | 63 | 10 | |

| 12.4 | 2.8 | 56 | 8 | 25 | 3.8 | 67 | 10 | |

| 31 | 4.2 | 76 | 12 |

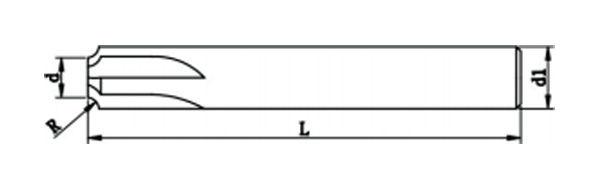

Engineering Data

special four-sided grinding

R plastic

straight slot

| d | R | d1 | L | d | R | d1 | L | |

| 3 | 0.5 | 4 | 38 | 4 | 3 | 10 | 60 | |

| 2 | 1 | 4 | 38 | 2 | 4 | 10 | 60 | |

| 5 | 0.5 | 6 | 38 | 6 | 3 | 12 | 60 | |

| 4 | 1 | 6 | 38 | 4 | 4 | 12 | 60 | |

| 2 | 2 | 6 | 38 | 10 | 3 | 16 | 70 | |

| 7 | 0.5 | 8 | 40 | 8 | 4 | 16 | 70 | |

| 6 | 1 | 8 | 40 | 6 | 5 | 70 | ||

| 4 | 2 | 8 | 40 | 14 | 3 | 20 | 80 | |

| 7 | 1.5 | 10 | 60 | 12 | 4 | 20 | 80 | |

| 6 | 2 | 10 | 60 | 10 | 5 | 20 | 80 | |

| 8 | 6 | 20 | 80 |