Special 4-face grinding with cobalt collar A coating (TiAlN) on the head protects the cutting edge area to a large extent and prevents wear effectively. Optimised flute type greatly improves the chip removal performance of deep hole drilling, helix angle, unique tool body guidance improves the machining accuracy of the hole.

Solid carbide spiral drill for deep hole machining, ideal for carbide drill bit set applications, featuring special four-sided grinding and TiAlN coating for enhanced precision and durability.

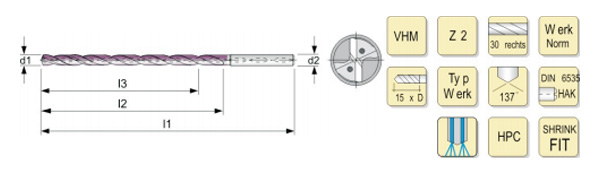

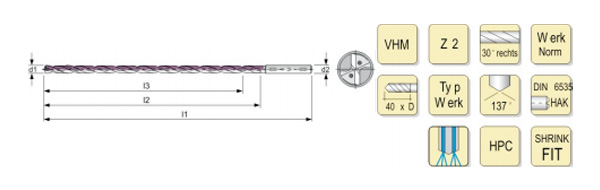

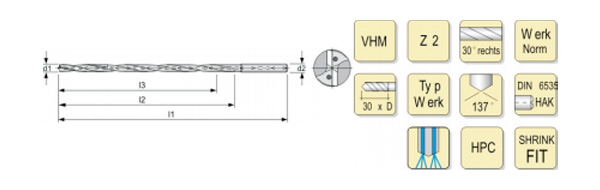

Engineering Data

special four-sided grinding

special point grinding

special chip flute geometry

4 guide chamfer

unique cutter guide to improve the processing precision of hole

| dl | L3 | L2 | L1 | d2 | dl | L3 | L2 | L1 | d2 | |

| (h7) | mm | mm | mm | (h6) | (h7) | mm | mm | mm | (h6) | |

| mm | mm | mm | mm | |||||||

| 3 | 45 | 51 | 95 | 6 | 7 | 105 | 119 | 160 | 8 | |

| 4 | 60 | 68 | 110 | 6 | 8 | 120 | 136 | 175 | 8 | |

| 4.5 | 57.5 | 76.5 | 120 | 6 | 8.5 | 127.5 | 144.5 | 190 | 10 | |

| 5 | 75 | 85 | 125 | 6 | 10 | 150 | 170 | 215 | 10 | |

| 5.5 | 82.5 | 93.5 | 135 | 6 | 12 | 180 | 204 | 255 | 12 | |

| 6 | 90 | 102 | 140 | 6 | 14 | 210 | 238 | 285 | 14 | |

| 6.5 | 97.5 | 10.5 | 150 | 8 |

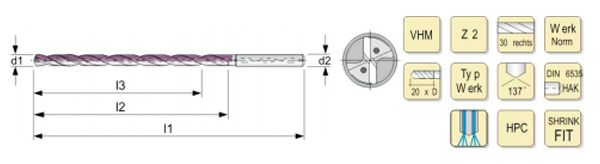

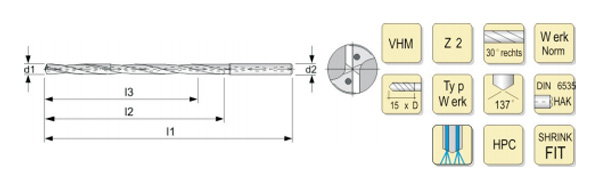

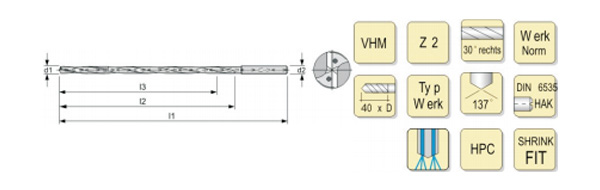

Engineering Data

special four-sided grinding

special point grinding

special chip flute geometry

4 guide chamfer

unique cutter guide to improve the processing precision of hole

| d1 | L3 | L2 | L1 | d2 | d1 | L3 | L2 | L1 | d2 | |

| (h7) | mm | mm | mm | (h6) | (h7) | mm | mm | mm | (h6) | |

| mm | mm | mIm | Ⅲ | |||||||

| 3 | 60 | 66 | 110 | 6 | 6.5 | 130 | 143 | 185 | 8 | |

| 4 | 80 | 88 | 130 | 6 | 7 | 140 | 154 | 195 | 8 | |

| 4.5 | 90 | 99 | 140 | 6 | 8 | 160 | 176 | 215 | 8 | |

| 5 | 100 | 10 | 150 | 6 | 8.5 | 170 | 187 | 230 | 10 | |

| 5.5 | 110 | 121 | 160 | 6 | 10 | 200 | 220 | 265 | 10 | |

| 6 | 120 | 132 | 170 | 6 | 12 | 240 | 264 | 315 | 12 |

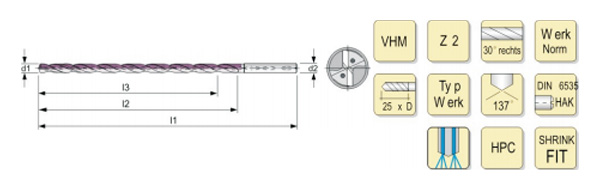

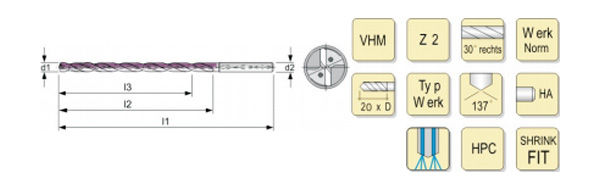

Engineering Data

special four-sided grinding

special point grinding

special chip flute geometry

4 guide chamfer

unique cutter guide to improve the processing precision of hole

| d1 | d2 | dl | d2 | |||||||

| (h7) | L3 | L2 | L1 | (h6) | (h7) | L3 | L2 | L1 | (h6) | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| 3 | 75 | 81 | 125 | 6 | 5.5 | 37.5 | 48.5 | 90 | 6 | |

| 4 | 100 | 108 | 150 | 6 | 6 | 150 | 162 | 200 | 6 | |

| 4.5 | 112.5 | 121.5 | 165 | 6 | 6.5 | 62.5 | 75.5 | 215 | 8 | |

| 5 | 125 | 135 | 175 | 6 | 8 | 200 | 216 | 255 | 8 | |

| 10 | 250 | 270 | 315 | 10 |

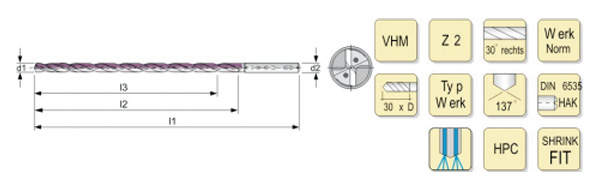

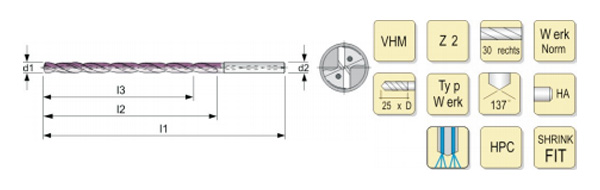

special four-sided grinding

special point grinding

special chip flute geometry

4 guide chamfer

unique cutter guide to improve the processing precision of hole

| dl | d2 | d1 | d2 | |||||||

| (h7) | L3 | L2 | L1 | (h6) | (h7) | L3 | L2 | L1 | (h6) | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| 3 | 90 | 96 | 140 | 6 | 5.5 | 165 | 176 | 215 | 6 | |

| 4 | 120 | 128 | 170 | 6 | 6 | 180 | 192 | 230 | 6 | |

| 4.5 | 135 | 144 | 185 | 6 | 6.5 | 195 | 208 | 250 | 8 | |

| 5 | 150 | 160 | 200 | 6 | 7 | 210 | 224 | 265 | 8 |

Engineering Data

special four-sided grinding

special point grinding

special chip flute geometry

4 guide chamfer

unique cutter guide to improve the processing precision of hole

| d1 | d2 | dl | d2 | |||||||

| (h7) | L3 | L2 | L1 | (h6) | (h7) | L3 | L2 | L1 | (h6) | |

| mm | mm | mm | mm | mm | mim | mm | mm | mm | mm | |

| 4 | 160 | 68 | 210 | 6 | 5 | 200 | 210 | 250 | 6 |

Engineering Data

special four-sided grinding

special point grinding

special polish chip flute geometry

4 guide chamfer

30° RH helix

unique cutter guide to improve the processing precision of hole

| d1 | d2 | d1 | d2 | |||||||

| (h7) | L3 | L2 | L1 | (h6) | (h7) | L3 | L2 | L1 | (h6) | |

| mm | mm | mm | mm | mm | mm | mm | mm | nm | mm | |

| 3 | 45 | 51 | 95 | 6 | 7 | 105 | 119 | 160 | 8 | |

| 4 | 60 | 68 | 10 | 6 | 8 | 120 | 136 | 175 | 8 | |

| 4.5 | 67 | 76.5 | 20 | 6 | 8.5 | 127.5 | 144.5 | 190 | 10 | |

| 5 | 75 | 85 | 125 | 6 | ||||||

| 5.5 | 82.5 | 93.5 | 135 | 6 | 10 | 150 | 170 | 215 | 10 | |

| 6 | 90 | 102 | 140 | 6 | 12 | 180 | 204 | 255 | 12 | |

| 6.5 | 97.5 | 110.5 | 150 | 8 | 14 | 210 | 238 | 285 | 14 |

Engineering Data

special four-sided grinding

special point grinding

special polish chip flute geometry

4 guide chamfer

30° RH helix

unique cutter guide to improve the processing precision of hole

| dl | d2 | dl | cd2 | |||||||

| (h7) | L3 | L2 | L1 | (h6) | (h7) | L3 | L2 | L1 | (h6) | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| 3 | 60 | 66 | 110 | 6 | 6.5 | 130 | 143 | 185 | 8 | |

| 4 | 80 | 88 | 130 | 6 | 7 | 140 | 154 | 195 | 8 | |

| 4.5 | 90 | 99 | 140 | 6 | 8 | 160 | 176 | 215 | 8 | |

| 5 | 100 | 10 | 150 | 6 | 8.5 | 170 | 187 | 230 | 10 | |

| 5.5 | 110 | 121 | 160 | 6 | 10 | 200 | 220 | 265 | 10 | |

| 6 | 120 | 32 | 170 | 6 | 12 | 240 | 264 | 315 | 12 |

Engineering Data

special four-sided grinding

special point grinding

special polish chip flute geometry

30° RH helix

unique cutter guide to improve the processing precision of hole

| d1 | L3 | d2 | d1 | L3 | d2 | |||||

| (h7) mm | mm | L2 | L1 | (h6) | (h7) | mm | L2 | L1 | (h6) | |

| mm | mm | mm | mm | mm | mm | mm | ||||

| 3 | 75 | 81 | 125 | 6 | 6 | 150 | 162 | 200 | 6 | |

| 4 | 100 | 108 | 150 | 6 | 6.5 | 162 | 175.5 | 215 | 8 | |

| 4.5 | 112.5 | 21.5 | 165 | 6 | 8 | 200 | 216 | 255 | 8 | |

| 5 | 125 | 135 | 175 | 6 | 10 | 250 | 270 | 315 | 10 | |

| 5.5 | 137.5 | 148.5 | 190 | 6 |

Engineering Data

special four-sided grinding

special point grinding

special polish chip flute geometry

30° RH helix

unique cutter guide to improve the processing precision of hole

| dl | d2 | d1 | d2 | |||||||

| (h7) | L3 | 12 | L1 | (h6) | (h7) | L3 | L2 | L1 | (h6) | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | ||

| 3 | 90 | 96 | 40 | 6 | 5.5 | 165 | 176 | 215 | 6 | |

| 4 | 120 | 128 | 170 | 6 | 6 | 180 | 192 | 230 | 6 | |

| 4.5 | 135 | 144 | 185 | 6 | 6.5 | 195 | 208 | 250 | 8 | |

| 5 | 150 | 160 | 200 | 6 | 7 | 210 | 224 | 265 | 8 |

Engineering Data

special four-sided grinding

special point grinding

special polish chip flute geometry

30° RH helix

unique cutter guide to improve the processing precision of hole

| d1 | d2 | d1 | d2 | |||||||

| (h7) | L3 | L2 | L1 | (h6) | (h7) | L3 | L2 | L1 | (h6) | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| 4 | 160 | 168 | 210 | 6 | 5 | 210 | 210 | 250 | 6 |